Revolutionary Carbon Nanotube Electric Motors: The Future of Lightweight, Metal-Free Power Systems

Revolutionary Carbon Nanotube Electric Motors: The Future of Lightweight, Metal-Free Power Systems

The Carbon Nanotube Revolution in Electric Motors

Traditional electric motors have long relied on copper and aluminum wiring for their electromagnetic coils. However, researchers have now created a revolutionary alternative using carbon nanotubes (CNTs) that promises to change everything we know about electric motor design. This breakthrough technology introduces Core-Sheath Composite Electric Cables (CSCEC) that eliminate the need for heavy metal conductors while maintaining exceptional electrical performance.

The new carbon nanotube-based motor represents more than just a scientific achievement – it's a paradigm shift toward lighter, more efficient electrical systems that could transform industries from automotive to aerospace.

Understanding the CSCEC Technology

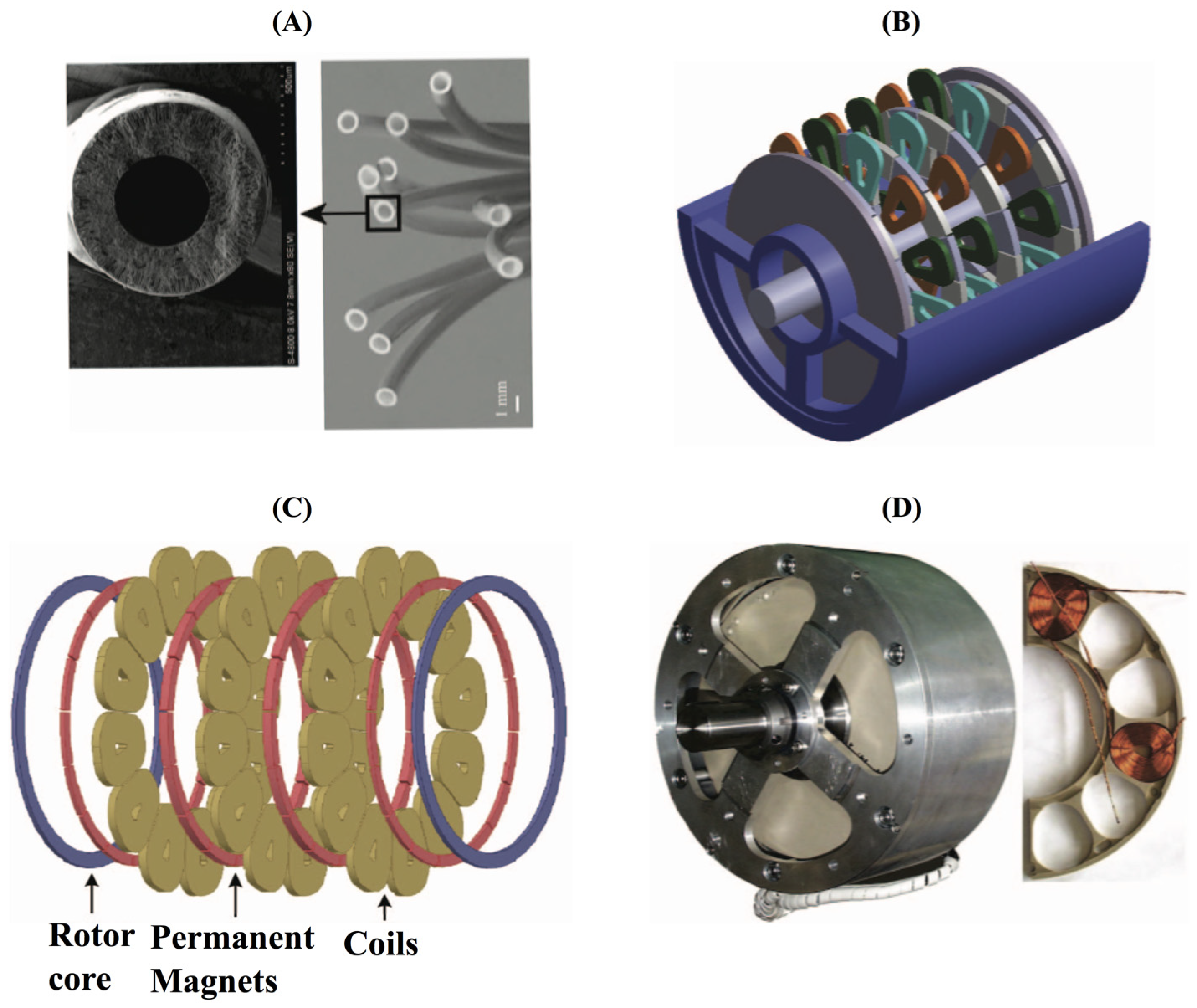

The heart of this innovation lies in the Core-Sheath Composite Electric Cables (CSCEC), which utilize carbon nanotubes instead of traditional copper wiring. These remarkable cables measure just 0.3 millimeters in thickness, including insulation, yet deliver impressive electrical conductivity. The conductor core spans approximately 256 micrometers with a 10-micrometer protective sheath – roughly the thickness of a business card.

Dr. Dae-Yoon Kim of KIST explains the significance: "By developing a new concept of CNT high-quality technology that has never existed before, we were able to maximize the electrical performance of CNT coils to drive electric motors without metal."

This achievement demonstrates that carbon nanotube technology has matured to the point where it can practically replace conventional metal conductors.

The LAST Process: A Manufacturing Breakthrough

The key to making carbon nanotube motors viable lies in the Lyotropic Liquid Crystal-Assisted Surface Texturing (LAST) process. This sophisticated manufacturing technique addresses one of the biggest challenges in carbon nanotube technology – maintaining proper alignment and separation of individual nanotubes.

The LAST process uses lyotropic liquid crystals, which represent a unique phase of matter that flows like liquid while maintaining directional order similar to crystals. This property allows the process to align carbon nanotubes effectively while preventing them from clumping together, which would reduce their electrical performance.

Combined with specialized chemical rinses, the LAST process removes metal catalyst impurities that accumulate during manufacturing. This purification step is crucial because it maintains the one-dimensional nanostructure that gives carbon nanotubes their exceptional properties.

The results are impressive: the LAST procedure increases conductivity by over 130% while dramatically reducing weight and ensuring stable long-term performance of the CSCEC cables.

Weight Reduction and Performance Benefits

Weight reduction represents one of the most compelling advantages of carbon nanotube motors. In applications where every gram matters – such as electric vehicles, drones, and aerospace systems – this technology offers substantial benefits.

Consider the practical implications for electric vehicles. A Tesla Model S uses dual motors weighing approximately 70 pounds (31.8 kg) for the front motor and 80 pounds (36.3 kg) for the rear motor. Copper windings account for roughly 25% of this weight. Replacing these copper components with CSCEC wiring could reduce the total motor weight from 150 pounds (68 kg) to approximately 115 pounds (52.2 kg).

While this 35-pound reduction might seem modest for a vehicle weighing over 4,500 pounds, the benefits extend far beyond simple weight savings. Lower rotating mass translates to faster spin-up times, improved throttle response, more efficient torque delivery, and reduced mechanical losses. Additionally, lower thermal loads allow for smaller, lighter cooling systems, creating a cascading effect that enhances overall vehicle efficiency.

Real-World Testing and Performance Metrics

The KIST research team conducted extensive testing to validate their carbon nanotube motor technology. Their prototype motor operated between 2 and 3 volts at 3.5 watts – specifications suitable for small-scale applications and proof-of-concept demonstrations.

While these power levels are significantly lower than full-scale automotive applications, the testing provided valuable insights into the technology's potential. The carbon nanotube motor achieved a maximum speed of 3,420 RPM, compared to 18,120 RPM for an equivalent copper motor under identical conditions.

However, when considering specific rotational velocity – a critical metric in aerospace applications where weight often matters more than raw power – the carbon nanotube motor performed remarkably well. Its specific rotational velocity was only 1.06 times lower than the copper equivalent, despite the conductor core weighing just one-fifth as much.

Conductivity Challenges and Solutions

Despite significant improvements through the LAST process, carbon nanotube wiring still faces conductivity challenges compared to traditional copper. CNT wiring achieves approximately 7.7 megasiemens per meter of electrical conductivity, while copper delivers 59 MS/m under similar conditions.

This conductivity difference means that for identical physical dimensions and voltage, carbon nanotube wires carry less current, resulting in lower power output. However, researchers are actively working to bridge this gap through various optimization strategies.

Future improvements focus on optimizing polymer sheaths and achieving better carbon nanotube alignment during manufacturing. These enhancements could significantly boost conductivity, bringing carbon nanotube performance closer to copper levels while maintaining the substantial weight advantages.

Economic Considerations and Manufacturing Costs

The economic viability of carbon nanotube motors presents both challenges and opportunities. Currently, specialized CSCEC cables cost between $375-500 per kilogram to manufacture, compared to copper's modest $10-11 per kilogram.

This significant cost difference reflects the sophisticated manufacturing processes required for high-quality carbon nanotubes and the relatively small scale of current production. However, as demand increases and manufacturing processes improve, costs are expected to decrease substantially.

Additionally, the total cost analysis must consider the broader system benefits. Weight reduction can lead to smaller batteries in electric vehicles, reduced fuel consumption in aircraft, and improved performance across various applications. These system-level benefits often justify the higher initial material costs.

Applications Beyond Automotive

While electric vehicles represent an obvious application for carbon nanotube motors, the technology's potential extends far beyond automotive uses. Aerospace applications, where weight reduction is paramount, could benefit enormously from this innovation.

Consider electric vertical takeoff and landing (eVTOL) aircraft, which require multiple motors and extensive wiring harnesses. A typical eVTOL might contain 200-300 pounds of copper wiring for redundant systems, plus 180-240 pounds of copper windings across six motors. Replacing this copper with carbon nanotube alternatives could reduce aircraft weight by 300-500 pounds – a substantial improvement that directly translates to increased payload capacity, extended range, or enhanced safety margins.

Environmental Impact and Sustainability

The environmental implications of carbon nanotube motor technology present a complex picture. While the motors themselves offer improved efficiency and reduced material usage, the manufacturing process currently relies on energy-intensive procedures that generate toxic byproducts.

The LAST process, for example, uses chlorosulfonic acid and produces hydrochloric acid during the rinse stage. Most carbon nanotube production still depends on fossil fuel feedstocks and energy-hungry manufacturing processes. However, researchers are actively developing more sustainable production methods that could address these environmental concerns.

As the technology matures, improvements in manufacturing efficiency and the development of renewable energy-powered production facilities could significantly reduce the environmental footprint of carbon nanotube motors.

Future Developments and Research Directions

The success of KIST's carbon nanotube motor opens numerous avenues for future research and development. Key areas of focus include:

Conductivity Enhancement: Continued research into carbon nanotube alignment, purification, and composite materials could further improve electrical conductivity while maintaining weight advantages.

Scaling Manufacturing: Developing more efficient, cost-effective production methods will be crucial for commercial viability and widespread adoption.

System Integration: Engineers must develop new design approaches that optimize entire systems around carbon nanotube technology rather than simply replacing copper components.

High-Voltage Applications: Expanding the technology to handle higher voltages and power levels will be essential for automotive and industrial applications.

Conclusion: A New Era in Electric Motor Technology

The development of carbon nanotube electric motors represents a significant step toward more efficient, lightweight electrical systems. While challenges remain in terms of conductivity, cost, and manufacturing scalability, the potential benefits are substantial enough to drive continued research and investment.

As the technology continues to evolve, we can expect to see carbon nanotube motors find applications in increasingly demanding environments, from electric vehicles to aerospace systems. The success of KIST's research demonstrates that the future of electric motors may indeed be metal-free, opening new possibilities for sustainable, high-performance electrical systems.

This breakthrough technology exemplifies how advanced materials science can revolutionize traditional engineering approaches, creating solutions that seemed impossible just a few years ago. As carbon nanotube motor technology matures, it will likely play a crucial role in the ongoing transition to more sustainable and efficient electrical systems across multiple industries.

Open Your Mind !!!

Source: NewAtlas

Comments

Post a Comment